01 Jun Electric cable reels

Project Description

Industry:

Government / Defence – Electrical, instrumentation, communication and maintenance services

Problem:

The project required the services of a specialised reel manufacturer to provide breathing air, supply air, exhaust air, compressed air, communications and power cabling reels, control panels, cabling and all necessary auxiliaries and interfaces to provide a complete service reel system as specified on the project scope of works

Solution:

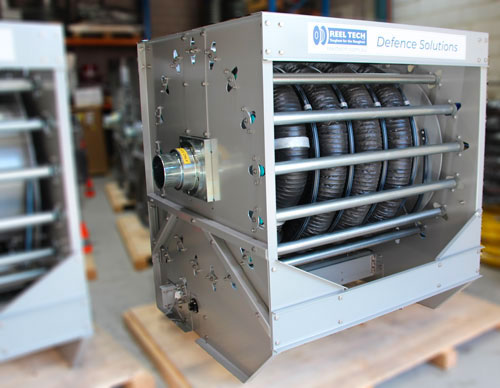

ELECTRIC CABLE REELS WITH LEVEL WIND GUIDE FOR REMOTE LOCATIONS

Reel-Tech specialises in many custom engineered reeling solutions for some of the most demanding applications. The company has extensive experience in reel customisation and have the technical capabilities to provide unique solutions to many of its client’s strict and complex specifications. The key to their success is through innovative product solutions that are derived from years of mechanical engineering and field experience. On such occasion, their engineered solutions division has been able to meet and exceed the client’s imperatives from delivery, quality, functionality and overall cost.

Reel-Tech once again was able to achieve the client’s full design objectives, providing fully engineered products that include some of the following features:

- The remote location of the reels in situ means that the reels are relatively inaccessible to the operators. This creates complexity from a reeling perspective since the reeling operation (deployment and retract) will need to function without any user intervention as typically required on standard reels. To tackle this problem, Reel Tech has incorporated unique technologies that they have developed in-house which include; FlatWinder™ level wind system to automatically guide and layer the hose/cable on the reel spool, (HCS) Hose Control System to control hose expansion allowing for seamless and trouble-free operation, and Limit Switch mechanisms to prevent hose/cable overrun.

- The reels were constructed in heavy gauge steel construction for strength and durability as these reels will be subject to excessive stress during their operational lifespan. Each reel componentry underwent thorough material selection to ensure that it meets the client’s strict requirements and are suitable for the required service.

- The 3-phase 415V AC drive system has been sized according to the client’s specifications which includes provision for torque and realigned speed control adjustment as would be required by operators for safety.

- The reels utilise high-end electrical componentry sourced only from trusted and reputable suppliers for performance and longevity. This includes high-quality precious metal contacts for better performance and corrosion resistance, precision deep groove ball bearings for reduced load and enhanced mechanical life, and fully certified for global applications conforming to local and international standards.

In addition, Reel-Tech was also able to satisfy the client’s quality assurance requirements including FAT (Factory Acceptance Testing) in-house and product support materials and documentation.

Hose Reel Implemented:

- Custom Reel Tech DDE-N700 Series Reel, Direct Drive Electric Rewind, 415V AC Motor, 4-Way Roller Assembly in VR Position, 3000 PSI, 1/2″ NPT-F In/Out Connections, c/w Full-Flow 90˚ SuperSwivel Joint, Pre-Primed & Painted Graphite Silver.

- Custom Reel Tech DDE-N700 Series Reel, Direct Drive Electric Rewind, 415V AC Motor, 4-Way Roller Assembly in VR Position, SS Hub, 1000 PSI, 1/2″ NPT-F Inlet x 3/8 NPT-F Outlet Connections, c/w SS Full-Flow 90˚ SuperSwivel Joint, Pre-Primed & Painted Graphite Silver.

- Custom Reel Tech 6” Series Reel, Electric Rewind, 415V AC Motor, Flat Winder™ Hose Layering System with 4-Way Roller Assembly in VR Position, Steel Hub, 6” (150mm) In/Out Connections, Powder Coated Silver Finish.

- Custom Reel Tech 6” VAC Series Reel, Electric Rewind, 415V AC Motor, Flat Winder™ Hose Layering System with 4-Way Roller Assembly in VR Position, Steel Hub, 6” (150mm) In/Out Connections, Vacuum Service, Powder Coated Silver Finish.

- Custom Reel Tech DDE-NSCR700 Series Cable Reel, Direct Drive Electric Rewind, 415V AC Motor, 4-Way Roller Assembly in VR Position, MFL 9-Conductor x 30A x 440V IP68 Collector Assembly, Pre-Primed & Painted Graphite Silver.

- Custom Reel Tech DDE-NSCR700 Series Cable Reel, Direct Drive Electric Rewind, 415V AC Motor, 4-Way Roller Assembly in VR Position, Ethernet Capable Collector Assembly – Non-IP Rated, Pre-Primed & Painted Graphite Silver.